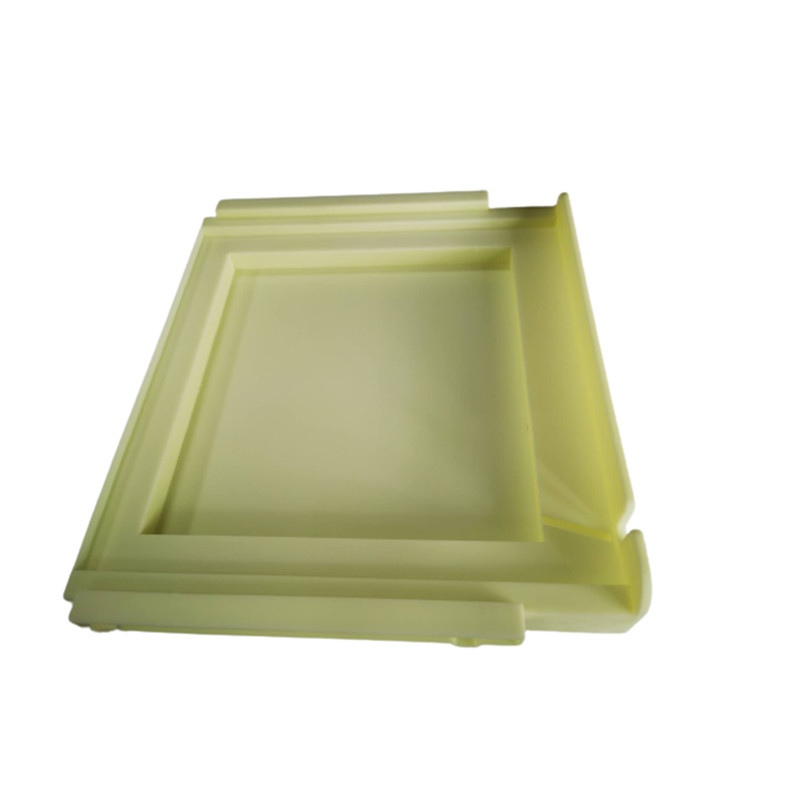

Plastic and metal components of medical equipment, appearance prototype

Discover our factory's expertly crafted plastic and metal components for medical equipment. Get a glimpse of perfection with our appearance prototype.

Request a QuotePRODUCTS DETAILS

Hot Products

Custom Black ABS Resin CNC Machining Parts Plastic Prototypes

Custom Zinked Steel Sheet Metal Components

Customized metal parts stainless steel part stretching&spinning factory OEM service

Customized 3D Printing ABS Plastic Parts SLA Printing Rapid Prototype

OEM high-quality galvanized steel sheet metal bending service

OEM CNC Machining Parts Stainless Steel Turning Miling Parts

Fabrication high-quality 3D printing plastic part services

OEM precision 3D printed metal parts service manufacturer

Plastic and metal components of medical equipment, appearance prototype

Custom Precision CNC Machined Aluminum Sandblasting Parts Manufacturing

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours